86-0371-55682180

No. 4 Group, Chuling Village, Chaohua Town, Xinmi, Henan, China (Mainland)

A refractory product with periclase as the main mineral component. According to the different composition of raw materials, it can be divided into: magnesium brick made of brick magnesia, magnesium alumino brick added with a small amount of special grade alumina or industrial alumina, magnesia carbon brick added with a certain amount of graphite powder, with poor quality. Magnesia-silica brick made of high-silica magnesia. Compared with other refractory bricks, magnesia bricks have higher refractoriness, up to 2000 °C, high load softening temperature, large high temperature mechanical strength, and good resistance to iron oxide and calcium oxide. The chemical attack properties of alkaline slag. However, the general thermal stability is poor.

The magnesium oxide content in the product is about 85%. An alkaline refractory material having an alumina content of 5% to 10%, a periclite-based crystal phase, and a magnesium-aluminum spinel as a sub-crystalline phase (as a main binder phase). The apparent porosity is generally 15 to 18%. The coefficient of thermal expansion is 10.6 x 10-6 / °C. The thermal shock resistance is better than the corresponding magnesia brick. Since the matrix has a high melting point of magnesium aluminate spinel, the high temperature strength is higher, and the load softening start temperature is above 1580 °C. The slag resistance is also good. Generally, high-quality sintered magnesia is used as a granular material, and a fine powder composed of magnesia or bauxite clinker or industrial alumina mixed with a certain proportion is added, and is obtained by kneading, molding and firing.

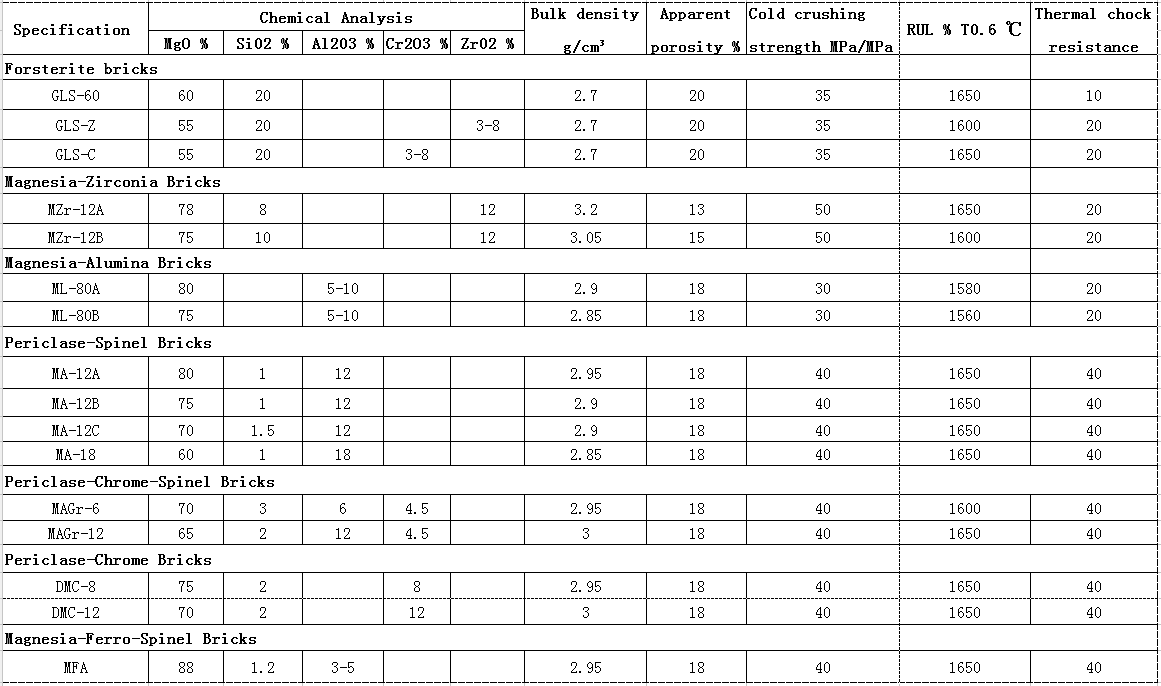

physical and chemical indicators of magnesia chrome brick

Material and performance index of magnesia chrome brick for cement kiln

After the Second World War, magnesia-chrome bricks began to replace the high-temperature belts of clay bricks and high-alumina bricks into cement rotary kiln. In China, the use of magnesia-chrome bricks is about 30 years later than abroad. In the early 1980s, a large number of chemically bonded unfired bricks were used. At about 1000 ° C, the bricks are weakened and damaged by the chemical bonding bonds due to the dissociation failure of the binder in the brick. Especially in the lower transition zone, the brick is peeled off thickly under the effect of reduction. At present, unburned bricks have been replaced by calcined magnesia chrome bricks in large precalciners.

Magnesia-chrome bricks Natural fused ore or its selected products and sintered magnesia made of natural or synthetic raw materials are the basic raw materials for the manufacture of magnesia chrome bricks. Ordinary magnesia chrome bricks or silicates combined with magnesia chrome bricks (containing 4% to 7% SiO2) combined with a lower melting point of the cinnamate phase (calcium-magnesium olivine CMS and magnesium-scruzzo C3MS2) combined with high refractory Magnesia and chrome, iron and aluminum composite magnesium spinel are formed, so Magnesia-chrome bricks has high high temperature plasticity and microstructure toughness. It shows stress relaxation above 800 °C and good thermal shock stability. It is most suitable for 1000t. Used in small kiln below /d. However, its load softening temperature is low, and it is easy to be damaged by overheating, so Magnesia-chrome bricks rarely used in large precalcining kiln (≥4000t/d).

Magnesia-chrome bricks with low silicate content (including 2.5%~4% SiO2) still have certain microstructure toughness and high temperature stability, which is suitable for use in rotary kiln of 1500~4000t/d. It can also be used on both sides of the firing zone in the larger format rotary kiln. This brick can be referred to as a semi-direct combined magnesium chrome brick.

Magnesia-chrome bricks When the silicate content is extremely low (including 0.5%~2.5% SiO2), the periclase in the brick is directly combined with the composite spinel, and the high temperature resistance is greatly improved, but the microstructure toughness is very poor, to 1200. The stress relaxation in the brick lining occurs above °C, which seriously weakens the thermal shock stability, alkali corrosion resistance and resistance to oxidation-reduction atmosphere of the brick. This type of brick is called a direct combination of magnesia chrome bricks and is mainly used in the firing zone of large rotary kiln. However, this brick requires a pre-decomposed kiln cement clinker firing system to operate stably, and try to use raw materials and fuels with low alkali content to prolong its service life.

Magnesia-chrome bricks Transitional or extrapolated bricks may also be present between or outside of the above-mentioned magnesia chrome bricks. The series of magnesia chrome bricks have a SiO2 content of 7% to 6%, 4% to 2.5%, <2.5% to <1%, and 8% to 16% Cr2O3, 70% to 80% MgO, at normal temperature and high temperature strength. The thermal shock stability, thermal expansion coefficient, load softening temperature and other properties have corresponding changes to meet the different needs of the above various kiln. In recent years, under the urgent requirement of preventing chromium pollution, in industrialized countries, the use of dolomite bricks (and spinel bricks) in the firing zone, and the replacement of magnesia chrome bricks using spinel bricks in the transition zone are undergoing rapid changes.

Classification of alkaline refractory bricks for cement kiln

First, magnesia chrome brick

Magnesia chrome brick is a traditional refractory material. Among the magnesia refractories, Cr2O3 can promote direct bonding and form magnesium chrome spinel, which plays an important role in improving the high temperature performance, thermal shock resistance, erosion resistance and kiln skin properties of refractories. However, in high temperature, oxidizing atmosphere and alkaline environment, Cr3+ will turn into highly toxic and carcinogenic Cr6+, which will cause great harm to the ecological environment.

Magnesia chrome brick,In order to reduce the pollution caused by Cr6+ in magnesia-chrome bricks, the first is to use magnesia-chrome bricks with low Cr2O3 content, and secondly to reduce the use of magnesia-chrome bricks. Table 1 shows the performance comparison of low chromium magnesia chrome bricks with recombined magnesia chrome bricks. Low-chromium magnesia-chrome bricks are made of high-iron magnesia and chromite. At high temperature, Fe2O3 in high-iron magnesia is dissolved in periclase; during cooling, MgO·Fe2O3 precipitates from the periclase crystals, forming a small hemp-like magnesia spinel dispersed in the periclase.

Magnesia chrome brick,Therefore, iron oxide has little effect on the high temperature performance of refractory materials. In other words, the technical point of the low-chromium magnesia-chrome brick is to replace a part of the magnesia-chrome spinel with magnesia spinel, and to exert the beneficial effects of Fe2O3 and Cr2O3 by limiting the harmful effects of Fe2O3.

Second, magnesium calcium brick

Magnesium-calcium refractories have good high temperature resistance, excellent kiln skin resistance and resistance to chemical cracking of cement clinker, but they are easy to hydrate and have poor thermal shock resistance, especially not resistant to CO2 and SO2. Gas erosion. In use, the CO2 and SO2 in the kiln will enter the brick along the pores, and minerals such as CaCO3 and CaSO4 will be formed in the middle and low temperature parts of the brick to cause the brick to expand and crack. Therefore, the dolomite bricks are used in the stable area of the kiln to obtain a satisfactory life.

Third, chromium-free magnesium material

Various chromium-free alkaline refractories were prepared by using iron-aluminum spinel, magnesium iron spinel, magnesium-aluminum spinel and zirconia instead of chromite.

The iron-aluminum spinel brick is made of magnesia and pre-synthesized iron-aluminum spinel. During calcination, Fe diffuses out of the iron-aluminum spinel particles into the matrix, forming a solid solution of periclase-magnesium iron spinel, which improves the skin properties of the kiln. At the same time, Mg diffuses into the iron-aluminum spinel particles to form a magnesium-aluminum spinel skirt around the iron-aluminum spinel, which reduces the sensitivity of the brick to the atmosphere. Despite this, the high-temperature and corrosion resistance of the iron-aluminum spinel bricks is still insufficient, and it is necessary to obtain the protection of the kiln skin to obtain a long service life.

Magnesia-iron spinel brick is made of magnesia-alumina spinel instead of chromite in low-chromium magnesia-chrome brick, and further improves the kiln skin property by adjusting the amount and distribution of iron oxide or magnesium iron spinel. . Similar to iron-aluminum spinel bricks, mafia bricks also require kiln skin protection for longer life.

If magnesium iron spinel bricks and iron-aluminum spinel bricks are not used, magnesium-aluminum spinel bricks can also be used for the firing zone. In order to improve the corrosion resistance of calcium oxide and the ability to hang kiln skin, the alumina content of the magnesia-alumina spinel brick used in the firing zone is lower than that of the magnesium-aluminum spinel brick used in the transition zone. In order to further improve the corrosion resistance and the kiln skin, fused magnesia-alumina spinel may be used instead of sintered magnesium-aluminum spinel, or zirconia may be substituted for part of the magnesium-aluminum spinel.

Zirconium oxide is an additive that can improve the performance of magnesium materials in an all-round way, but it is expensive and suitable for small quantities.

1)Raw material to factory→checkout→burdening→stirring→mixing→taking out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

2.Inspection and control of the process: during the production,every brick will be weighed twice strictly to reduce the error of weight .

3.Quality audit by quality management: inspection of product standardization of quality of each product by process control and experimentation, taking corrective measures timely whenever deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance, physical and chemical properties of brick again in factory.

Packaging of diatomaceous bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of diatomaceous bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity guaranteed, and also in accordance with the contract and customer's requirment completely.

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".Our company is willing to develop a wide range of technical exchanges with colleges and universities and colleagues from all walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.For different industries, the cement industry with anti-flaking high-alumina bricks, alkali resistant bricks, phosphate bricks;Boiler industry USES all kinds of brand wear-resisting brick, corundum brick, mullite brick and other finalizing materials.The company insists on "product quality is the life, enterprise integrity is the foundation", in the fierce market competition, won many users' trust and praise.The products are sold all over the country, as far as Vietnam, India, Korea, Pakistan, kazakhstan, Iran and other southeast Asian countries and regions.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our aim."Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service.Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

1. Quality assurance,zircon bricks use high grade raw material. All products are ISO qualified.

2. Provide professional designing solution, field technical assitance and any other consulting.

3. Price advantage, provided by manufacturer directly,save much intermediate fees.

4. Professional and experienced service team, specialized in refractory production since 1986.

5. Large production capacity, short lead time of products.

6. 24*7 online service.

7. OEM service available.